Jewelry manufacturing process is the backbone of every high-quality jewelry collection sold in global markets.

Behind each finished piece lies a carefully controlled sequence of technical, creative, and quality-driven stages.

For brands, wholesalers, and private-label businesses, understanding this process helps ensure consistency, scalability, and long-term profitability.

In this guide, we take an in-depth look at how professional jewelry manufacturers transform raw materials into market-ready jewelry.

Overview of the Jewelry Manufacturing Process

The jewelry manufacturing process is a structured production workflow designed to ensure precision, durability, and visual consistency.

Professional manufacturers follow standardized systems to:

- Maintain quality across batches

- Control production costs

- Meet international compliance standards

- Deliver on-time at scale

Each stage plays a critical role in the final outcome.

Stage 1: Raw Material Sourcing & Metal Selection

Everything begins with sourcing the right raw materials.

Manufacturers select metals based on:

- Design requirements

- Market positioning

- Cost targets

- Regional compliance standards

Commonly used metals include gold, silver, brass, and custom alloys.

Ethical sourcing and traceability are increasingly important for global brands.

Stage 2: Alloying & Metal Preparation

Pure metals are rarely used directly.

They are alloyed to:

- Improve strength

- Enhance durability

- Achieve specific color tones

Precise alloy ratios are essential for consistency in the jewelry manufacturing process.

Once alloyed, metals are melted and prepared for casting.

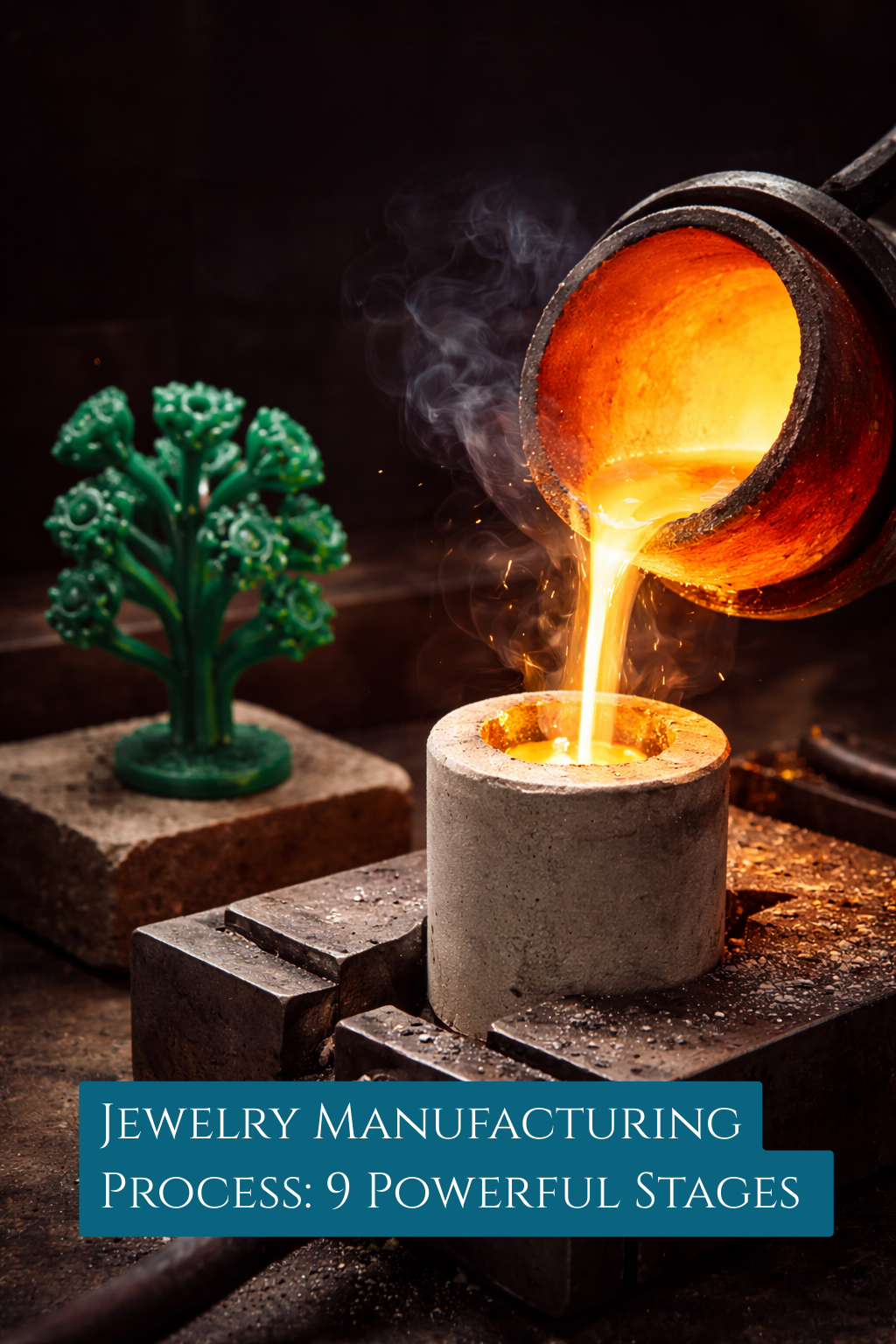

Stage 3: Casting Methods in Jewelry Manufacturing

Casting is where designs begin to take physical form.

Popular casting methods include:

- Lost wax casting

- Investment casting

- Die casting (for high-volume production)

Each method is chosen based on:

- Design complexity

- Production volume

- Required precision

Controlled casting ensures structural integrity and accurate dimensions.

Stage 4: Cleaning, Filing & Pre-Finishing

After casting, pieces undergo initial cleaning.

This stage removes:

- Excess metal

- Sprues and casting marks

- Surface irregularities

Skilled technicians manually refine each piece to prepare it for setting and finishing.

This step directly affects final polish quality.

Stage 5: Stone Setting Techniques

Stone setting is one of the most delicate stages in the jewelry manufacturing process.

Common techniques include:

- Prong setting

- Bezel setting

- Pavé setting

- Channel setting

Precision is critical to ensure:

- Stone security

- Visual symmetry

- Long-term durability

Experienced setters are essential for premium-quality output.

Stage 6: Polishing & Surface Finishing

Polishing brings the jewelry to life.

Depending on design intent, finishes may include:

- High polish

- Matte or satin finish

- Brushed textures

- Electroplating

This stage enhances visual appeal and prepares the piece for market presentation.

Stage 7: Quality Control & Inspection

Quality control is non-negotiable in professional jewelry manufacturing.

Each piece is inspected for:

- Dimensional accuracy

- Stone security

- Surface finish

- Structural strength

Multiple inspection points reduce defects and returns.

Strong QC systems protect brand reputation.

Stage 8: Production Standards for Global Markets

Manufacturers serving international clients must meet global production standards.

This includes:

- Consistent metal purity

- Export-ready finishing

- Compliance with regional regulations

- Batch-level traceability

Meeting these standards allows brands to scale confidently across markets.

Stage 9: Packaging & Final Dispatch

The final stage of the jewelry manufacturing process is secure packaging and dispatch.

Professional packaging ensures:

- Protection during transit

- Brand-ready presentation

- Accurate order fulfillment

Timely dispatch completes the manufacturing cycle.

Why Process Control Matters for B2B Buyers

For B2B clients, process control equals predictability.

A structured jewelry manufacturing process delivers:

- Reliable quality

- Stable pricing

- Consistent timelines

- Long-term production partnerships

This is why experienced manufacturers are preferred over unstructured workshops.

Explore Zona Creation’s full capabilities on our

👉 Products & Services page

👉 Contact Us page

You may also find value in our related article on the Custom Jewelry Design Process in the blog section.

Precision Is the Heart of Jewelry Manufacturing

A high-quality jewelry collection is built on discipline, expertise, and process control.

The jewelry manufacturing process ensures that every piece meets design intent, durability standards, and global market expectations.

At Zona Creation, we specialize in structured, scalable jewelry manufacturing for brands, wholesalers, and private-label businesses.

If you’re planning your next jewelry collection, we’re here to help.

Frequently Asked Questions

The jewelry manufacturing process is a professional production workflow that converts raw metals and materials into finished jewelry. It includes metal sourcing, casting, stone setting, polishing, quality control, and final packaging.

Professional jewelry manufacturing commonly uses gold, silver, brass, and custom alloys. The choice depends on design requirements, target market, pricing strategy, and regional compliance standards.

The best casting method depends on design complexity and production volume. Lost wax casting is ideal for detailed designs, while die casting is preferred for high-volume, repeatable production.

Quality control ensures dimensional accuracy, stone security, finish consistency, and durability. Strong QC systems reduce defects, protect brand reputation, and meet global market standards.

Production timelines vary based on design complexity and order size. For most B2B projects, the jewelry manufacturing process takes 3 to 6 weeks after final design approval.